Stunning Colored Chrome Paint by the Best

If you’re looking for an innovative way to customize your vehicle or other project, consider Cosmichrome spray on chrome paint. With its unique chrome-like finish, this spray paint provides a stunning, eye-catching look in many colors.

Cosmichrome is a revolutionary spray on chrome paint that provides a durable, mirror-like finish. This high-quality coating is a blend of paint and plating. Use Cosmichrome to coat almost any surface, including aluminum, steel, plastic, and more. Furthermore, it’s highly resistant to UV rays, chemicals, and other environmental factors so it won’t fade over time. (Guaranteed!)

One of the best features of Cosmichrome is that it’s available in a wide range of colors. From classic chrome to vibrant hues like purple, blue, and red, you’ll be able to choose the perfect color for your project. And unlike most chrome paint, Cosmichrome is designed to be used on both interior and exterior surfaces. Merely add one of our twenty colors to our top coat to produce a spectrum of chrome colors

Whether you need to give your project a unique look or customize your parts with a custom color, Cosmichrome is the perfect choice. Cosmichrome is a great way to add color to your project without sacrificing quality. With its long-lasting finish and vibrant color options, this spray on chrome paint is sure to give your project an eye-catching look. So if you’re looking to add a unique, colored chrome finish to your builds, Cosmichrome is the perfect choice.

Czarnowski Collective Creates Signs Using Cosmichrome Spray Chrome

Challenge: How to create chrome signs?

Solution: Cosmichrome Spray Chrome!

Czarnowski recently completed a project that showcased their signmaking capabilities and the versatility of Cosmichrome spray chrome. The project involved creating large foam Chevy Bow Tie signs and coating them with Cosmichrome spray chrome. Cosmichrome is a revolutionary spray chrome paint that provides a durable, mirror-like finish. It is a great alternative to traditional chrome plating, as it is much faster and more cost-effective. It is also environmentally friendlier, than traditional chromium electroplating. The challenge was how to create chrome signs and with which product.

Czarnowski used their expertise in signmaking to create these large foam Chevy Bow Tie signs. They used a CNC router to cut the foam into the desired shape and size. Once the foam was cut, they applied a primer to the surface to level the foam and to ensure that the Cosmichrome spray chrome would adhere properly. Once the primer was dry, they applied the Cosmichrome spray chrome. The spray chrome was applied in three layers, with each layer being allowed to dry before the next layer was applied. This process was repeated until the desired finish was achieved. The end result was a stunning set of large foam Chevy Bow Tie signs that were coated with a durable, mirror-like finish in both chrome and gold. The signs were a great example of the versatility of Cosmichrome spray chrome and the signmaking capabilities of Czarnowski.

If you are looking for a cost-effective and environmentally friendly way to achieve a chrome finish, then Cosmichrome spray chrome is the perfect solution. It is fast, economical, and provides a durable, mirror-like finish in a dozens of different chrome colors.

Hydrochrome Switches to Cosmichrome for the Win!

The experts at Hydrochrome in California have made switched their spray chrome supplier to Cosmichrome. Since they switched to Cosmichrome, rejects are way down, production is up, and they have eliminated parts turning yellow. You can visit their website by clicking here Hydrochrome Home Page. Hydrochrome coats a range of different parts including large sculptures destined for casinos to automotive parts.

Take a look at some of their work below. They’ve even coated parts for a build on the Netflix Series, Car Masters in cooperation with Gotham Garage. If you need to improve your spray chrome business, talk to us about switching to Cosmichrome. You’ll be happy you did.

Cosmichrome Statue

Balloon Animal Sculptures

Pink Balloon Animal Sculptures

Multi Colored Balloon Animal Sculptures

Huge Dome For A Casino

Classic Car Grill

Larger than Life Statue For A Casino

Decorative Panels

Decorative Panels

Skull

Bumpers

Red Cosmichrome Dash Board

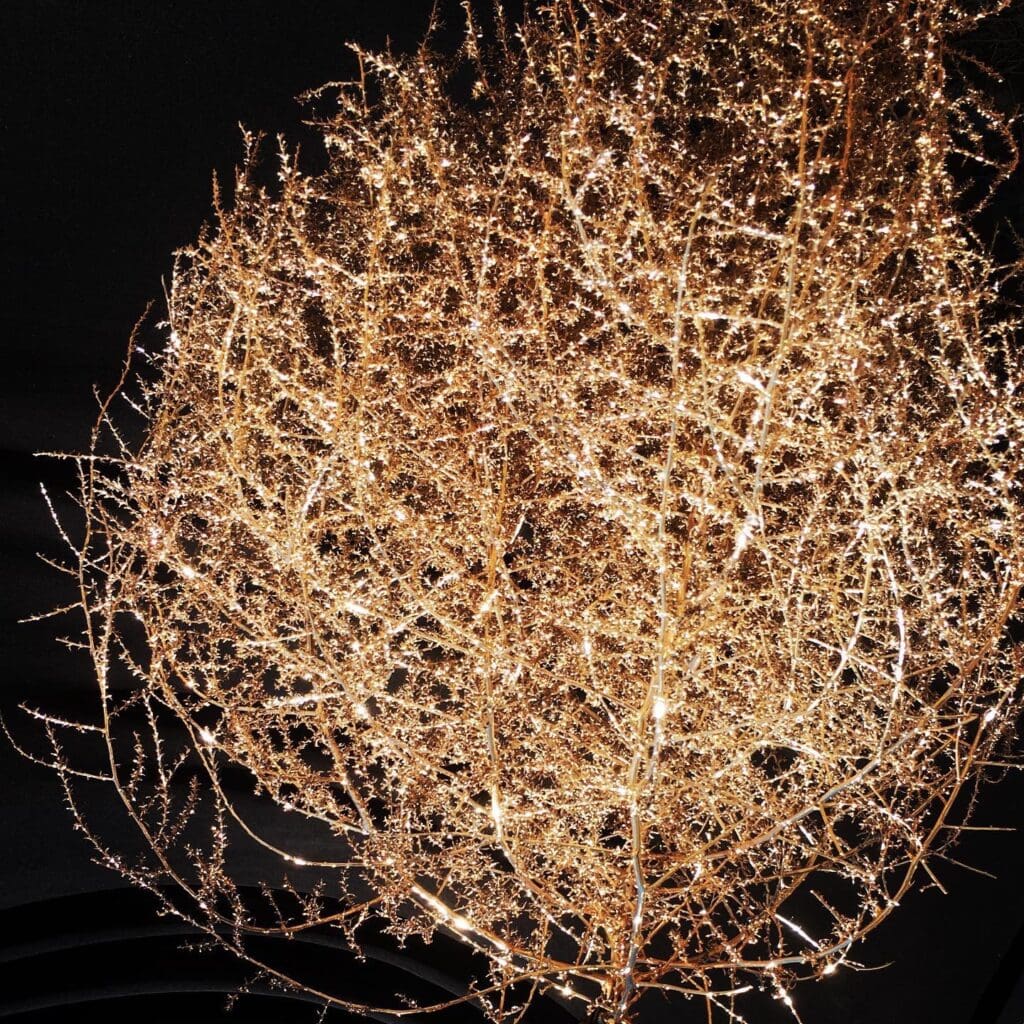

Gold Tinted Tumble Weed

Cosmichrome Bath Tub by Hydrochrome

Cosmichrome Bath Tub

Cosmichrome Bath Tub by Hydrochrome

Cosmichrome Bath Tub by Hydrochrome

Hydrochrome used Cosmichrome on the build with Gotham Garage. They can be seen on the Netflix Series, Car Masters.

Hydrochrome used Cosmichrome on the build with Gotham Garage. They can be seen on the Netflix Series, Car Masters.

Car Masters Interior

Side Vents

Helmets and sculptures

Avalon King’s Glowing Review of The Cosmichrome System

The fine folks at Avalon King wrote an unsolicited review of Cosmichrome. The article explains Cosmichrome in depth. It covers the invention of chrome electroplating and explains in detail the Cosmichrome process, its advantages, and its exclusive non-yellowing spray chrome process.

Get Your Shine On: A Close Look at Cosmichrome Spray-on Chrome Coatings

Off Axis Paint Teams Up With Cosmichrome

Off Axis Paint is a certified NASCAR helmet painter. They paint a considerable number of the helmets worn by NASCAR drivers. Off Axis Teamed up with Cosmichrome to offer chrome helmets to the drivers. We are proud they selected Cosmichrome as their spray chrome. Cosmichrome is the only spray chrome that can meet the demands of Off Axis Paint. The taping and cutting used to produce their designs would destroy competing spray chrome products. Those spray on chromes would just peel apart when the tape is removed. Cosmichrome won’t fail cutting and taping.

Restoring antiques with nickel plating and rose gold plating

Rose Gold and Silver Plated Razors

Silver Plated Antique Razors

Silver Plated Antique Razors

These restored antique luxury razors are all electroplated with our cyanide-free plating chemicals. Chris Spencer has switched to our TiveNi-Mirror nickel plating solution after many years in the the plating and restoration business. TivaNi-Mirror is brighter than any nickel he has ever used.

These Razors are finished in non cyanide TivaGlo-Free™ Rose Gold Plating Solution and TivaSilva-Free™ non cyanide silver plating solution. The results are stunning.

We thank Chris for sharing his great results. You can see more of his work at https://backroadsgold.com

Camaro Tech Visits Cosmichrome at the 2019 SEMA Show

We are always very busy at the SEMA Show. Cosmichrome at the 2019 SEMA Show was no exception. One reason we are so busy is that we do live demonstrations at the show right in our booth. We built a mini spray booth to apply the water based layer of our process. Live demonstrations give visitors a chance to try Cosmichrome’s unique process for themselves.

The Patented E-Gun Select™ makes the process easy enough that anyone can apply the chrome finish. There’s not guessing if the chemicals are spraying at the correct ratio. The metal comes out perfect even for absolute beginners.

You’ll get to see much of the rest of the 2019 Cosmichrome booth in this video too. One of our show cars, lots of customer made helmets and other amazing spray chrome parts coated with the only non yellowing spray chrome on Earth.

Thanks to Camaro Tech for filming this clip.

If you’d like to receive more information on getting a Cosmichrome system, Send un an email with your request. We will be happy to help you.

Official SATA Distributor

We Recommend SATA Paint guns for the best Cosmichrome finish

When you are spray a finish as smooth and reflective as Cosmichrome you need the finest paint guns to get a perfectly smooth finish. An inferior paint gun will produce a rough, orange peel finish in the chrome. You can’t hide orange peel in a finish that needs to be as smooth as chrome plating.

Using the right paint gun will make a remarkable difference in the quality of your final Cosmichrome finish. Remember, you are trying to simulate very smooth chrome electroplating. An inexpensive paint gun will not perform well enough to give the best results. You spent the money on the right Spray Chrome machine when you bought a Cosmichrome system. Get the right paint gun too.

We recommend the SATAjet 5000B HVLP with a 1.3mm tip. The digital model is shown below. A standard model is also available for a lower price. Please tell us which model you prefer.

See us at the 2019 SEMA Show

Las Vegas Convention Center

North Hall

Booth #10709.

Be sure to see us at the 2019 SEMA Show in Las Vegas. This will be our 27th year at the SEMA show! There will be show specials, demonstrations and new products. November 5th-9th, 2019

Register at The SEMA Show

Meet Ryno Templeton from West Coast Customs in our booth.

Get hands on demonstrations every hour.

Safely and easily remove the spray chrome metal without harming the base coat.

Cosmichrome keeps minor mistakes from becoming disasters.

Cosmichrome is the only spray chrome that allows you to safely and easily remove the spray chrome metal without harming the base coat. If you notice a defect in your plating you can just remove the silver with bleach, then re-spray the Cosmichrome! No need to sand and re-apply the base coat!

Touching the base coat of competing spray chrome products is forbidden. Touching the base coat ruins their base coat finish and it will have to be sanded and re-applied. This drawback can add days to your project, sanding and waiting for base coat to dry. Cosmichrome allows you to simply remove the metal layer and re-spray the metal. This is a major technical advancement in spray chrome. Everyone makes a mistake once in a while.

Achieving a perfect chrome spray plating is easy when you remain aware of all the parameters that can have an impact on the results. Like all professional paint projects, these parameters range from temperature, humidity, dust, fingerprints, and so on. Thankfully, there is a way to salvage your part without having to sand your part and re-apply the base coat! Bleaching the base coat to re-plate a part is easy to do with Cosmichrome BCL base coat.

Bleaching A Part For Re-Plating

BLEACH THE PART!

WHAT YOU’LL NEED:

- RUBBER GLOVES

- MICROFIBER CLOTH

- SOFT BLUE SHOP TOWELS

- CUP OF BLEACH

- COSMICHROME BASECOAT CLEANER

- THE PART TO BE BLEACHED

*NOTE: This process can only be done if the Topcoat has not yet been applied to the part.*

THE PROCESS

The part that needs re-plating will need the plating to first be removed.

We begin this process by saturating our soft blue shop towels into the cup of bleach. After it is well saturated, gently rub the bleach into the part. The chrome should begin to quickly dissolve and reveal the Basecoat underneath. Continue to rub and wipe away the plating until all the plating is removed. Re-soak your shop towel in bleach and remove any residual plating residue. Grab a new shop towel, soak in bleach and wipe down the piece as a final rundown. Now rinse your part very thoroughly with distilled water to remove any leftover bleach. Be aware that any leftover bleach will oxidize the metal and make the product look yellow! So rinse very well!

Now that the old plating is gone, we can prepare the part for re-plating.

Apply Cosmichrome Base Coat Cleaner to the part to clean the base coat for re-plating. Gently rub in the Basecoat Cleaner into the part. Be careful to not apply too much pressure. Now, rinse away Basecoat Cleaner with distilled water.

Now re-flame the part to prepare it for re-plating. After that, apply the A22 Activator solution. This activates the Basecoat for plating adhesion. Rinse again with distilled water, getting rid of any excess A22.

Time for re-plating.

Apply G4 & G5 plating solutions. Rinse with distilled water.

Congratulations! You have successfully re-plated a part!

Follow us on Facebook. https://facebook.com/cosmichrome

Follow us on Instagram https://Instagram.com/cosmichrome