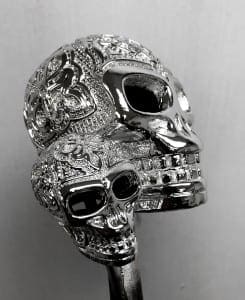

How to apply a chrome finish to a 3D print

If you are looking for how to apply a chrome finish to a 3D print your answer is here. Cosmichrome is ideal for applying simulated gold, chrome, copper and nickel finishes to 3D prints. The finish is applied in a paint booth. Most 3D model shops already have paint facilities so Cosmichrome is a logical addition to 3D part production. In this example the skulls are SLAs. I believe they were made in an Objet brand printer but I am not certain. They had a waxy residue from the setup material that I cleaned off with a toothbrush and alcohol. I mounted the prints to dowels using hot glue. Then I applied an Epoxy primer because I wasn’t certain how well I had removed the residue. Unfortunately the primer never hardened so I removed it with lacquer thinner and got fresh epoxy primer from the local paint store. I then let the primed part and let it dry over night at room temperature.

Then I applied Cosmichrome base coat. I applied three layers to be sure I got good coverage down in the low spots in all the detail on the model. I let the base coat dry over night at room temperature. The base coat can also be baked to speed up the drying process but on delicate 3D prints heat can distort the shape of the part so room temperature drying is the safest choice. After the base coat was completely dried I flame (plasma) treated the base coat then proceeded to the plating process you can watch in the video below.

I let the part air dry in front of a fan for about twenty minutes and then applied the top coat. Here is the final result.

Huge Lombardi Trophy in Cosmichrome

Rose Gold is Hot!

Rose gold is very fashionable at the moment. We manufacture rose gold for electroplating that is very popular with jewelers and some people are plating car emblems with our brush rose gold too. You can simulate rose gold using Cosmichrome to take advantage of the rose gold surge in popularity. This is a sample of rose gold colored Cosmichrome created in our Montreal office.

Call or email us for the easy to mix formula.

Hydrographics over Cosmichrome

We are frequently asked if it is possible to create a hydrographics over chrome using Cosmichrome. We have several customers that do this and achieve incredible results. The following example was provided by our customer St. Louis Chrome. After he applied the complete Cosmichrome finish he used hydrographics or water transfer printing to place this pattern over the Cosmichrome chrome finish. We think the results are stunning.

Cadillac Elmiraj Concept Car

GM has been using Cosmichrome spray on chrome for nearly ten years. This stunning new Cadillac Elmiraj concept car features Cosmichrome trim, wheels and a new grill design with color tinted Cosmichrome. Jay Leno really appreciates the new grill. The Elmiraj is a large coupe. It is a rather remarkable concept car because it is really close to how a final production model might appear. We are proud to be the spray chrome supplier to General Motors.

Helicopter in Cosmichrome spray on chrome

Sundance Helicopters of Las Vegas is introducing their new fleet of Airbus helicopters featuring their new Cosmichrome spray on chrome paint scheme.

This helicopter spray chrome project was created by Air Methods and recently exhibited at the HAI Heli-Expo Show in Anaheim, CA. The aircraft features gold tinted Cosmichrome and regular chrome tinted Cosmichrome. Air Methods had tried several other spray chrome coatings before achieving amazing success with Cosmichrome. This is a an advanced spray chrome project that competing systems just couldn’t coat properly. They didn’t have the adequate intra coating adhesion and they just didn’t look good enough.

Eventually all Sundance Helicopters will be coated in Cosmichrome.

We’d like to thank Andretti Autosport for their recommendation!

Colorware, Inc. chooses Cosmichrome spray chrome

ColorWare was founded on the idea that electronic devices could be more appealing than the standard colors offered by the original manufacturer. ColorWare products are creative and fashionable, giving their customers something unique that sets them apart from all the rest.

ColorWare is the only company in the world where you can create your own bespoke electronic device. The range of products spans from headphones to computers, portable PC’s, phones and gaming consoles. They are experts at coating and branding.

ColorWare rocked the headphone market in 2011 by collaborating with Beats and producing a limited edition Chrome Dr Dre Beats headphones. ColorWare also supplies the Cosmichrome spray chrome coating on Sennheiser microphones. These stunning microphones are highly regarded by the world’s most famous recording artists.

No company is more demanding of quality and performance than ColorWare and we are proud to be their spray chrome supplier for the past three years.

Lady Gaga Statues

One of our customers was commissioned to spray chrome these very large Lady Gaga statues for her Artpop album introduction. The Cosmichrome was tinted to provide the gold and blue finishes. The Cosmichrome spray chrome was applied by Coat of Chrome.Coat of Chrome are experts at coating large objects. The amount of preparation and planning for this project was very challenging and had to be completed with a very tight deadline.This project was the result of a collaboration with sculptor Jeff Koons. Mr. Koons is one of the world’s leading modern artists. His work typically sells for millions of dollars.

Base Coat and Top Coat Updated for 2014

These chrome valve covers were spray chromed by our customer Sacramento Chrome and Paint https://sacchromepaint.net using our latest Cosmichrome base coat and top coat. They appear to be disappearing into the table or made of glass because the finish is so perfectly smooth and the color so accurate.

We have been able to significantly accelerate the drying of the top coat so your parts are ready to ship sooner.

The new base coat and top coat are in stock and ready to ship.

Cosmichrome process awarded US Patent

U.S.Patent #8,187,677

This patented technology is available for use only under license agreement.

Feature 1

Cosmichrome tolerates high temperatures.

350ºF is now the upper temperature limit. You can now bake the topcoat at high temperatures. There is no longer the 100ºF/40ºC top coat baking limit. Cosmichrome will not get foggy if over heated about 100ºF when the topcoat is wet. The maximum temperature is 300ºF. Flash off the topcoat for 20 minutes and then bake at higher temperatures for faster and more durable curing. Be careful your part does not melt. Parts that won’t tolerate high heat themselves will still melt.

Feature 2

Improved base coat filling, hiding and leveling.

As easy as our base coat has been to apply, it is even easier now. It hides substrate defects better. Less sanding and prep work is needed. Also it is even more reflective than before. S

Feature 3

Worry free 100% Reliable and Permanent Silver Adhesion to Base Coat.

As many of you already know, Cosmichrome has always had the best silver adhesion in the industry despite some of our competitors’ claims. With this new technology you will achieve perfect silver adhesion every time regardless of how long you dry the base coat. In fact, the only danger is under drying. The silver will adhere to the base coat even if the base coat has cross-linked and hardened. Let it dry a day, a week or even a month. It does not matter. Adhesion is perfect and permanent. Double activation uses our same A22 activator. No need to heat the Activator water unless it is cold.. Mix at room temp and it is ready in only 10 minutes. If the water is cold let it warm up to room temperature for an hour.

Feature 4

100% Reliably and Permanent Topcoat Adhesion to Silver.

Using an adhesion promoting clear coat, the topcoat adhesion is reliable under nearly any humidity conditions in the paint booth. As soon as all the water is blown off the part it is immediately coated with the adhesion promoter. The adhesion promoter is single component and does not contain isocyanates. No mixing. This coating takes about one hour to force dry with moving air. Heat is not necessary but can be used. It is then coated with the normal VU-13.

Feature 5

Excellent Thermal Shock.

Cosmichrome holds together during extreme and rapid temperature changes on substrates that have high coefficients of expansion such as urethane plastics. Go from the car wash to sub freezing temperatures with no problems.

Feature 6

Fast drying topcoat.

Feature 7

Does not turn yellow over time! All competing spray chrome are plagued with yellowing. Cosmichrome patented technology has eliminated this issue.

What this all means is that you will be able to produce a more durable finish that is much less sensitive to variations in the application. You will also be able to coat parts that are exposed to much higher temperatures than with competing products..

You will no longer have to worry about how long you baked the base coat and at what temperature. The dryer the better.

The base resistant to runs.

Meets or exceeds many if not most OEM paint standards.

Similar process to what we developed for LG’s production line but even more durable.

Reduces or eliminates many top coat reactions to contaminants.

Less sensitive to moisture and humidity during application and in the environment.

Weather and humidity will cause fewer problems during the application.

Own a competitor’s system?

We’ll help you face the world again!

Have you purchased a competing Spray On Chrome System?

Basecoat won’t lay out?

Poor success rate.?

1 in 10 parts come out okay?

Neglected to check for satisfied references?

Didn’t get samples or got pieces of tiles as samples?

Don’t Blame Yourself.

Dozens of companies have switched from competing spray chrome products to Cosmichrome™.

Are you tired of orange peel in your base coat?

Tired of burn marks around holes?

Tired of parts turning yellow in several months?

Silver fading away in a few months?

If you are disappointed with the results and durability of your competing system,

don’t be embarrassed. Call or email us for Help and references.