The Only Spray Chrome Guaranteed Not To Turn Yellow From The Sun

Red Cosmichrome Competitive Pulling TractorBy Pete's Rod Nest

Red Cosmichrome Competitive Pulling TractorBy Pete's Rod Nest NFL headquarters deskSprayed in Cosmichrome. New York City.

NFL headquarters deskSprayed in Cosmichrome. New York City. 50 ft Tall Chrome Lombardi TrophyRecord Breaking Spray Chrome Project in Cosmichrome

50 ft Tall Chrome Lombardi TrophyRecord Breaking Spray Chrome Project in Cosmichrome Indy 500 Winner Ryan Hunter-ReayOfficial supplier of Cosmichrome spray chrome.

Indy 500 Winner Ryan Hunter-ReayOfficial supplier of Cosmichrome spray chrome. Cosmichrome MicrophoneCoated by ColorWare, Inc. for Sennheiser

Cosmichrome MicrophoneCoated by ColorWare, Inc. for Sennheiser Lady Gaga Art Pop SculptureJeff Koons/Lady Gaga Collaboration

Lady Gaga Art Pop SculptureJeff Koons/Lady Gaga Collaboration

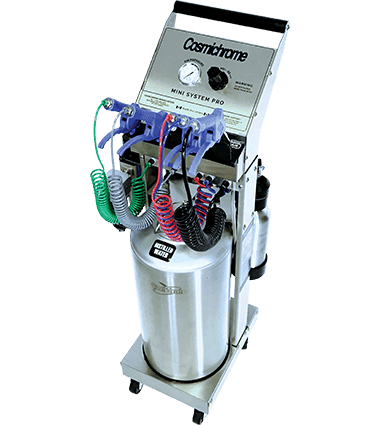

Mini System PRO™

MORE MINI SYSTEM PRO™ INFO

Ideal for small parts and low production.

Plates parts up to the size of a hubcap or helmet.

Economical to use yet provides excellent plating performance.

Provides precise and balanced ratio of the plating chemicals.

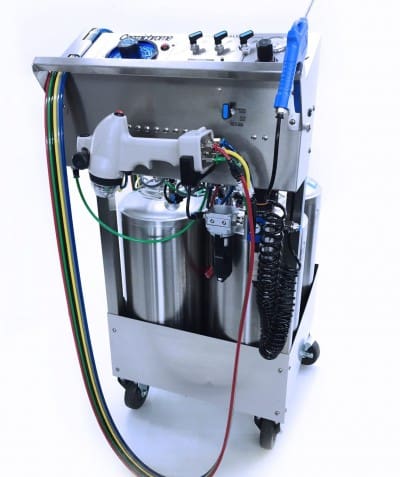

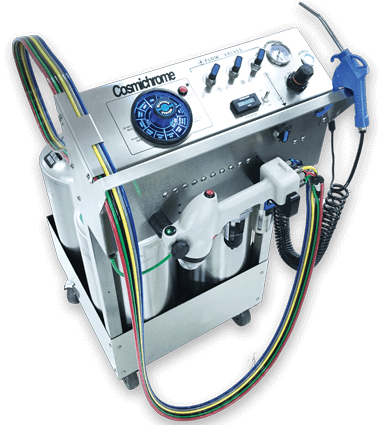

Master System PRO™

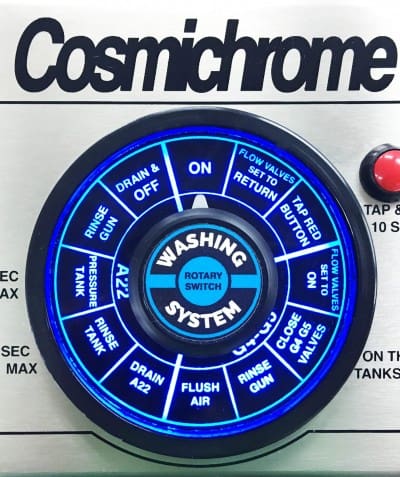

MORE MASTER SYSTEM PRO INFOA patented lightweight electronic gun (e-Gun Select™) applies all the chemicals. Just press a button to go through the process sequence! This simplifies the plating process and makes it easier to learn. We also introduce these new features for this new system. Built-in Automated Washing System.

Cosmichrome® is a patented spray chrome system. It’s a hybrid of proprietary paints and plating chemicals work together to allow you to spray a virtual chrome finish on nearly anything. Plastics, metals, ceramics, glass and even wood can be chromed. The end result is a finish that’s visually identical to chrome electroplating. Because Cosmichrome is sprayed on in a paint booth it eliminates size restrictions on the parts you chrome because tank size. Cosmichrome is the only spray chrome durable enough for many OEM uses. While most spray chrome systems are notoriously difficult to use, Cosmichrome is really different. We made the process as easy as possible with our patented machine and process. Not only is Cosmichrome the easiest spray chrome to apply, it is also the most durable.

Exclusive: Cleanable Base Coat

Now you can clean the base coat! If someone accidentally touches any competitor’s base coat you have to start over. Just wash Cosmichrome base coated part with our new Base Coat Cleaner and a soft paper towel. It’s totally safe. No scratches or fingerprints left behind to show in the metal. If you have used a competing system, you already know that touching the competing base coats will ruin your part 🙁 . You have to sand the part down and start over. Perhaps your cat ran across your perfect base coat finish. Maybe your assistant was eating a greasy burger and decided to move your base coated parts for you and left greasy fingerprints on the helmet you were about to chrome. Simply and safely wash the contaminants away with our base coat cleaner. :). This is a really unique and amazing feature that saves hours of lost time and do-overs.

Will Not Turn Yellow or Discolor Over Time!

No one needs angry customers returning parts to be redone because they turned yellow after a few months. Competing spray chrome paints are notorious for turning yellow after a few months. This is the most common reason people switch to Cosmichrome. Cosmichrome is the only spray chrome that won’t turn yellow in the sun. Guaranteed

Patented Spray Chrome Systems and Process

The patented Master System Pro™ is the most advanced, reliable and easy to use spray chrome machine on the market. Patented electronics assure a perfectly balanced spray, something other spray guns just can’t reliably produce. Cosmichrome’s perfectly balanced spray of the chrome chemicals, prevents streaky and discolored parts.

We eliminated trying to get the needle valves adjusted and opening simultaneously. The chemicals are perfectly balanced. We complete eliminated needle valve problems. The Select Gun™ simplifies the spray chrome process so that just about anyone can learn to apply a stunning spray chrome finish. The Master System Pro is highly engineered. It spray chrome work simpler and easier. Even cleanup is built-in and automatic.

One gun sprays all the chemicals. Simply click the red select button to proceed to the next step. LED lights indicate the chemical in use. This patented technology prevents mysterious random streaks and stains that plague other spray chrome products.

Advanced Adhesion Technology

We utilize advanced coating technology such as plasma treatment in our chrome paint process. It simplifies the spray chrome process and assure excellent adhesion. Brief exposure to plasma alters the distribution and density of electrons on the base coat’s surface. Because plasma polarizes surface molecules, adhesion of the metal onto the base coat is incredible. As a result, removing the metal layer with tape is impossible. This advanced feature is not available with competing systems. It’s just one of our many strengths and advantages, Even more importantly, plasma treatment eliminates streaks, stains and foggy chrome that plague competing spray chrome systems.

Switch to Cosmichrome

If you have a competing spray chrome kit there is a good chance we can help you. Our easy to use chrome chemicals and expert tech support will help you get immediate improvement. Don’t be afraid to call us for help. We have saved many businesses. Other chrome paint systems are just various brand paints and chemicals relabeled and cobbled together. As a result, they result in unreliable chrome plating. We make all our own chemicals from scratch. They are fine tuned to work together. Because we make all our own materials we’ve been able to help many businesses like yours finally succeed with spray chrome. Many struggled for years to get good results.

Trusted By the Best

Understandably, our customers apply Cosmichrome for companies like Trek Bikes, Cirque de Soleil, Lady Gaga, Disney, The National Football League, American Idol, Sennheiser and Beats, to name a few. It’s also used by West Coast Customs. Counting Cars, Off Axis Paint, and even General Motors.

Some Special Effects

Unique Features

- Won't yellow from the sun! This problem plagues competing spray chromes. Cosmichrome is guaranteed not to turn yellow indoors or outdoors.

- Cleanable base coat! Just wipe off accidental fingerprints. If you touch other base coats you have to sand the part down and start over. Our base coat is easy to clean with a soft paper towel and distilled water,

- Cut and buff our base coat! Eliminate dust particles or runs and other defects without having to reapply the base coat!

- If you make a plating mistake you can just remove the metal with bleach and reapply it without having to start over again and without reapplying the base coat. Just wash the part with our Base Coat Cleaner to remove the bleach.

- Tolerates much higher temperatures than any other spray chrome. Up to 350ºF/170ºC. Coat parts in the engine compartment without damaging the coating. (Exhaust parts are too hot, sorry).

- We utilize advanced coating technology such as plasma treatment in our process to simplify the spray chrome process and assure excellent adhesion. Brief exposure to the energized particles alters the distribution and density of electrons on the substrate’s surface and polarizes surface molecules. This advanced feature is not available in inferior competing systems and is one of our many strengths and advantages. It's one of the reasons Cosmichrome can be used on race cars, airplanes and helicopters without peeling.

- Cosmichrome top coat dries in 24 hours for light handling. It gets very hard yet remains flexible. It's also much easier to apply compared to competing systems.

- Cosmichrome G4 and G5 spray chrome solutions are long lasting. 90 days once mixed for the G4. 90 days for the G5 once opened. (no mixing of the G5 is required for simplicity). Competing spray chrome chemicals spoil after one day creating expensive waste. Any left overs must be discarded.

- Cosmichrome resists peeling, flaking better than any competing product.

- Meets many OEM automotive paints standards.

- Meets the European Union's RoHS rules. (Reduction of hazardous substances)

- US Patent 7,726,589

- US Patent 8,187,677

Free Training

We have training nearly every day by appointment at our Ohio office.

There are also monthly master classes in our Montreal office too. Just call or email us to set up a free training class.

Our customers also rely on our friendly expert phone and internet support

We have support in Spanish, Italian, Greek, Finnish, Swedish and French too.The Process = Three Layers

1. After the parts are prepped for painting, a proprietary paint is applied. This paint is the Cosmichrome base coat.2. When the base coat is dried properly it is plated with Cosmichrome using one of the Cosmichrome machines. The specific plating steps are:

- a. Plasma treatment

- (Distilled water rinse)

- b. Activator

- (Distilled water rinse)

- c. Cosmichrome® spray application

- (Distilled water rinse)

- d. Speed Seal

- (Distilled water rinse)

- e. Compressed air blow dry.

1. Guaranteed Not To Turn Yellow

2. Tolerates much higher temperatures than competing products. Use inside the engine compartment without yellowing or blistering

3. Our base coat is tough. If someone accidentally touches it you can wipe the fingerprints off with distilled water and a damp paper towel. Other products force you to start all over and apply new base coat.

4. Mixed Plating Chemicals Last 90 days, Competing chemicals expire at the end of the day. Leftovers are wasted.

5. Our base coat can't be over dried. Competing chemicals lose adhesion if the base coat dries to long but look foggy if the base coat isn't dry enough. You can let Cosmichrome base coat dry all weekend or accidentally bake it too long and there is no harm or loss of intra-coating adhesion. In fact the dryer our base coat the better the adhesion and shine.

6. Our top coat is simple to apply. Two medium wet coats and you are done.

7.Competing systems are plagued with what they call "champagne bubbles". Champagne may sound nice but it will give you horrible headaches. You are forced to apply layer after layer of dry coats of an untinted top coat to prevent bubbles before you can apply a wet coat of a chrome tinted top coat. Then after all that work, eventually your part eventually turns yellow. The yellowing may happen in a few weeks or a few months but it will happen even if the parts are never taken out doors. It's embarrassing and it will make your customers angry. You can do the part over but it will happen again. Cosmichrome top coat will not turn yellow.

During practice for the 2013 Indy 500 a car coated with a competing spray chrome product had a total adhesion failure. All their chrome peeled off in a big cloud of what looked like glitter. As far as we know it was the first time in history a car was back flagged at the Indy 500 for peeling paint.

- FAQ

Q: Can I use my own paints instead of the Cosmichrome® paints?

A: No. The metallic coating won’t adhere to other primers and other topcoats will not adhere to the metallic layer and will also discolor the metallic layer. Only original Cosmichrome™ coatings will provide intra-coating adhesion, accurate color and durability. You can apply your own paints above and below Cosmichrome™ but they can’t be substitued in place of the Cosmichrome™ paints.

Q: Is Cosmichrome a new product?

A: No. Cosmichrome has been on the market nearly six years. Cosmichrome has a proven track record. Our gallery pages show work done by many of our customers over the years. No competeing spray chrome product can match the durabilty and success of Cosmichrome.

Q: Do I need to apply a name brand topcoat to get good durability?

A: No. Cosmichrome VU-15 is an automotive quality topcoat. If you decide to use another name brand topcoat over the VU-15 you must let the VU-15 dry at least 3 days before applying another topcoat to eliminate the danger of melting through the VU-15 and which could cause the finish to yellow. VU-15 will not yellow. Name brand topcoats will eventually turn yellow if the touch the Cosmichrome plating layer.

Q: A competing system requires I use two separate topcoats and a name brand topcoat. Is Cosmichrome similar?

A: No. Cosmichrome VU-15 is all you will likely need. If you know your parts will be subject to extreme conditions then consider applying additional clearcoats after the VU-15 has dried at least 1 day.

Q: Why do I need a paint facility?

A: To keep dust out of the coating and to provide a proper working environment.

Q. Can it be applied to exhaust pipes?

A: No, The maximum temperature is 350ºF/ 174ºC. Even electroplated chromium plating will discolor on many high temperature parts. Many plastics melt well below these temperatures.

Q. How long does the process take?

A. Including drying times and baking, the process takes about 4 1/2 hours.

Q. Can I use infrared lights to bake the paints?

A. One must be careful to heat the parts evenly and to the correct temperature. Lights tend to heat unevenly. Its better to let the parts dry at room temperature than to heat them unevenly. If you make an enclosed “oven” with a black interior and use the lights to heat the walls of the oven you will have better luck with infrared lights. Use an infrared thermometer to check the temperature of the entire part to make sure its being heated evenly.

Q. Do I need to be an experienced painter?

A. Not necessarily. We have plenty of sucessful users that had little painting experience but were willing to learn. Even experienced painters must be willing to learn some new techniques to apply Cosmichrome™. The plating part of the process is not painting and must be learned whether or not you have much painting experience.

Q. Is Cosmichrome™ the same product as others I have seen sold by other companies?

A. No. Cosmichrome™ is made by Cosmichrome™, Inc. in Canada. We have used competing products and found them to be terribly inferior to Cosmichrome™. All Cosmichrome components are made by Cosmichrome, Inc. They do not merely re-label other products.

Why We're The Best

Shop Intelligently!

When shopping for a spray chrome system be sure to do your research. Study reviews on blogs, Youtube and get references. There are many copycat products on the market and none of them provide the technology and quality results of Cosmichrome.

We hear from unfortunate people nearly every day about the system they have providing disappointing results. Even if they can occasionally make acceptable looking parts they will likely turn yellow in a few weeks or months.

Cosmichrome is guaranteed not to turn yellow, a problem that plagues competing systems.

Cosmichrome Intro in 8 Minutes

The Basic Steps

Cosmichrome on Counting Cars

Cosmichrome West Coast Customs Kid Rock Episode

Cosmichrome Spray on Chrome Chemical Packages

| Chemical Package 1 | Chemical Package 2 | Chemical Package 3 | Chemical Package 4 |

| Base Coat 5L | Base Coat 5L x 3 | Base Coat 5L x 6 | Base Coat 5L x 10 |

| Base Coat Catalyst 1L x 2 | Base Coat Catalyst 1L x 6 | Base Coat Catalyst 1L x 12 | Base Coat Catalyst 1L x 20 |

| Chrome Top Coat 5L | Chrome Top Coat 5L x 3 | Chrome Top Coat 5L x 6 | Chrome Top Coat 5L x 10 |

| Top Coat Catalyst 1L x 2 | Top Coat Catalyst 1L x 6 | Top Coat Catalyst 1L x 12 | Top Coat Catalyst 1L x 20 |

| Activator A22 1L | Activator A22 1L x 3 | Activator A22 1L x 6 | Activator A22 1L x 12 |

| G4 Solution 18L | G4 Solution 18L x 3 | G4 Solution 18L x 6 | G4 Solution 18L x 12 |

| G5 Solution 18L | G5 Solution 18L x 3 | G5 Solution 18L x 6 | G5 Solution 18L x 12 |

| Speed Seal 1L | Speed Seal 1L x 3 | Speed Seal 1L x 6 | Speed Seal 1L x 12 |

MORE CHEMICAL INFO